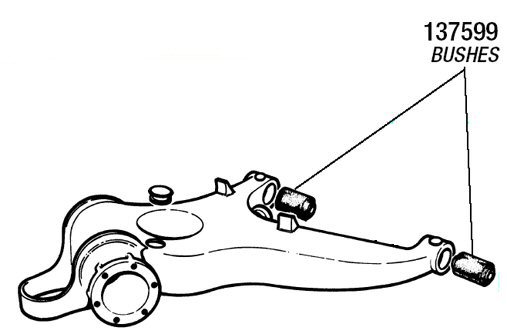

REPLACING SWINGING ARM BUSHES

Replacing the bushes is a straightforward procedure and it can be done without removing the arm from the car.

The shock absorber, spring and drive shaft can be left attached.

Remove the two bolts passing through the bushes and prise the arm free of the chassis and support it from below.

The ROM says “Press out trailing arm bushes/Press in trailing arm bushes.” Easier said than done!

There have been diagrams in the past to show how to do this but here are more accurate diagrams.

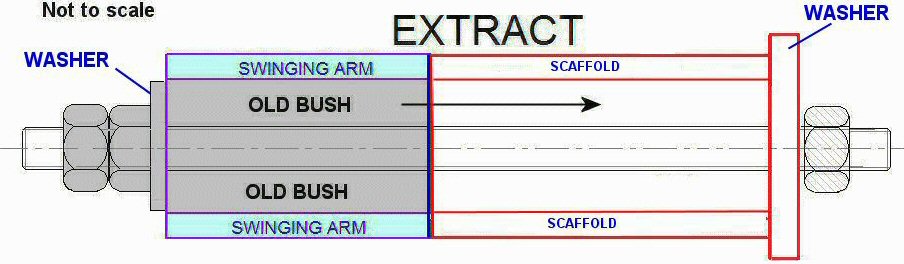

Firstly, remove the old bushes. They have been in there a long time and don’t want to come out.

The easiest way is to cut out most of the bush with a hole saw on an electric drill.

The rest can be cut with a hacksaw blade and either prised out with a screwdriver or removed using

the following method.

You will need a strong steel tube with an I/D about the same as the hole in the arm.

I found that a scaffold pole base was just the right size, and cut off two pieces to the lengths required.

You will also require some threaded rod and nuts, and some large thick washers.

Lock two nuts together on the rod, put on a washer and push the rod through the arm, scaffold tube and washer, and lock them together with a single nut.

The diagram shows how to put them together.

When the single nut is tightened the old bush is pulled into the scaffold.

Once the bush is removed clean the inside of the arm using abrasive paper.

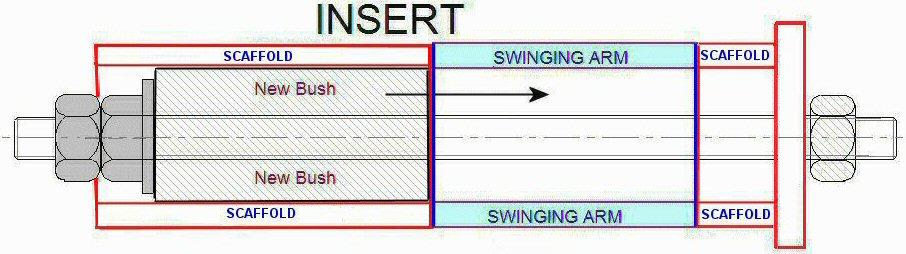

Inserting the new bush is done with a similar method but with a couple of changes.

Because the bush extends outside the arm slightly, I used a short piece of scaffold to give some room between the washer and the arm. This allows the bush to centralise in the arm. I also used silicon spray to lubricate the bush and arm to make insertion easier. The S/S sleeve was then inserted in the bush.

You can also use any other lubricant which doesn't affect the rubber or poly bushes e.g.

soapy water or KY Jelly ![]()

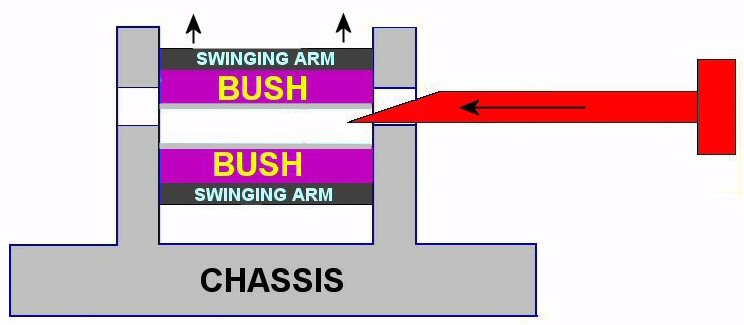

Now the bushes are in the arm and the arm needs to be reattached to the chassis.

Again this is easier said than done. The new bushes make it difficult to push the arm into the mountings as it is difficult to get a purchase. I used the jack to raise the arm into an approximate position but couldn’t get it exact.

I made a wedged drift by taking one of the old arm mounting bolts cutting the end off at about 30 deg, and rounded off the sharp edges.

I inserted the drift into the mounting hole and located it in the bush sleeve.

By tapping the bolt into the sleeve, the arm is pulled into the proper alignment.

The new mounting bolt is then inserted into the other end of the mounting, and tapped into place,

pushing the drift out as it enters.

Simples!